Bull Run Diverter Valve by Fluid Dynamic Siphons, Inc.

Introducing the Bull Run Diverter Valve

|

The Bull Run® Valve is designed to split effluent flow to distribution boxes. In addition to the advantages of longer life and easier installation the valve is the most public health safe alternating device available for wastewater disposal applications. The user has absolutely no contact with wastewater due to the valve's leak-proof and external operating characteristics. The changeover from one drainage field to another can be accomplished in less than a minute by simply turning a valve without digging or contact with wastewater. The Bull Run Valve is available in 4" and is suitable wherever septic tank disposal systems are used - in commercial, industrial, and residential application.

|

Operating the Bull Run Valve

Bull Run Valve Installation - Direct Burial

The valve is designed to be buried directly in the pipe trench requiring no concrete or hold down strap installation. The valve must be installed with the septic tank effluent line connected to the valve port marked "IN". The valve ports marked "OUT" are connected to each half of the drainfield. Adaptable to Various Piped Each valve port plus the riser tube connection are 4" schedule 40 female slip connections. Use ample PVC, ABS, or Multi-purpose glue to form a water-tight joint. Any of the following can be used to connect the Valve:

- Schedule 40 PVC or ABS pipe.

- Adapter Bushing (DWV hub to sewer & drain spigot)

- ASTM D 2729 (Schedule 30) coupling

- Bell end of ASTM D2729 (Schedule 30) pipe

Sample Valve Specification

A non-corrosive alternating valve shall be provided with 4" schedule 40 female connections. The valve plug shall be non-removable, water-tight, and externally operate. The valve shall be provided with an internal stop mechanism for positioning the plug, and the plug shall be non-jamming when turning from stop to stop. There shall be no metal parts in contact with the wastewater.

The inlet and outlet ports shall be clearly labeled for easy installation and the position of the valve shall be clearly indicated on top of the valve. At no time shall the operator have contact (physical or visual) with the wastewater. The valve shall be installed in such a manner as to be easily accessible from the ground surface and operated with a standard water key provided.

Simple instruction for use and maintenance, printed on durable material, shall be supplied along with each device. The valve shall be a Bull Run® Valve.

The inlet and outlet ports shall be clearly labeled for easy installation and the position of the valve shall be clearly indicated on top of the valve. At no time shall the operator have contact (physical or visual) with the wastewater. The valve shall be installed in such a manner as to be easily accessible from the ground surface and operated with a standard water key provided.

Simple instruction for use and maintenance, printed on durable material, shall be supplied along with each device. The valve shall be a Bull Run® Valve.

Operation by Water Meter Key

A riser cap adapter, a water-tight access cap and valve key are provided. The valve should be buried at such a depth as to allow easy access and operation from the ground surface with the standard water key provided.

Pump Systems

Effluent pumps can be used to dose the drainfield. The top of the valve is o-ring sealed and pressure tight under normal effluent pump operating conditions. Maximum pressure 25 psi.

The internal plug is tapered to match the valve body seating ribs. This seating mechanism will prevent by-pass under minimum head pressure conditions. To prevent by-pass under low pressure conditions, specify the Bull Run® Valve gasket.

The internal plug is tapered to match the valve body seating ribs. This seating mechanism will prevent by-pass under minimum head pressure conditions. To prevent by-pass under low pressure conditions, specify the Bull Run® Valve gasket.

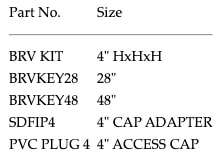

Complete Valve Kit Contains:

- Bull Run Valve Body

- 28" Valve Key

- Riser Cap Adapter

- Water-Tight Access Cap

©

Fluid Dynamic Siphons, Inc.